RunRight® Product Technology

- Maintenance Free Problem Solvers

- Leverages proprietary Tensys® rubber technology

- Can act as a spring, dampener, tensioner, and much much more

RunRight® Product Technology Information

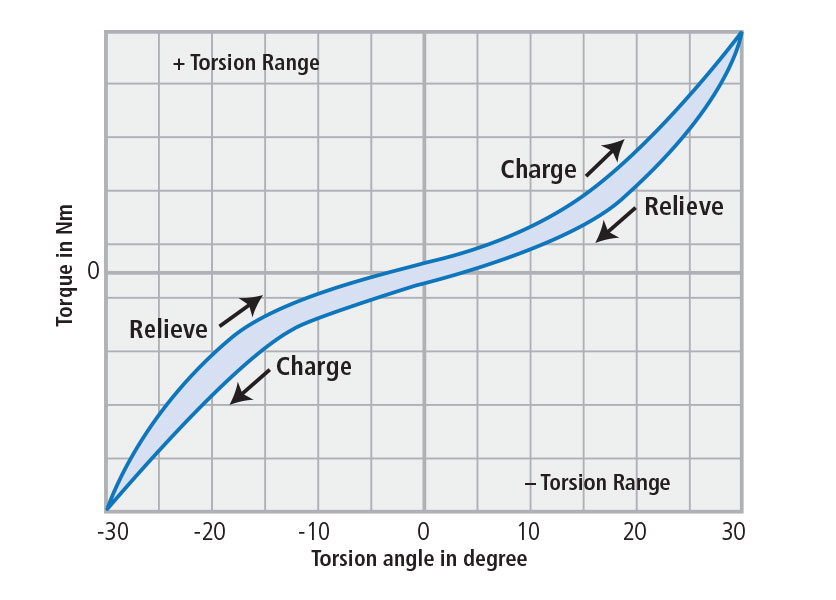

When the RunRight rubber suspension units are pivoted, a nearly linear spring characteristic occurs with a slightly progressive upper end, with a load applied close to a 30˚ rotation of the element. To obtain a functionally adapted spring characteristic, the leverage point may need to be altered and/or arm guidance may be needed through the use of a cam-disc. The volume of the elastomeric inserts will remain constant when in use.

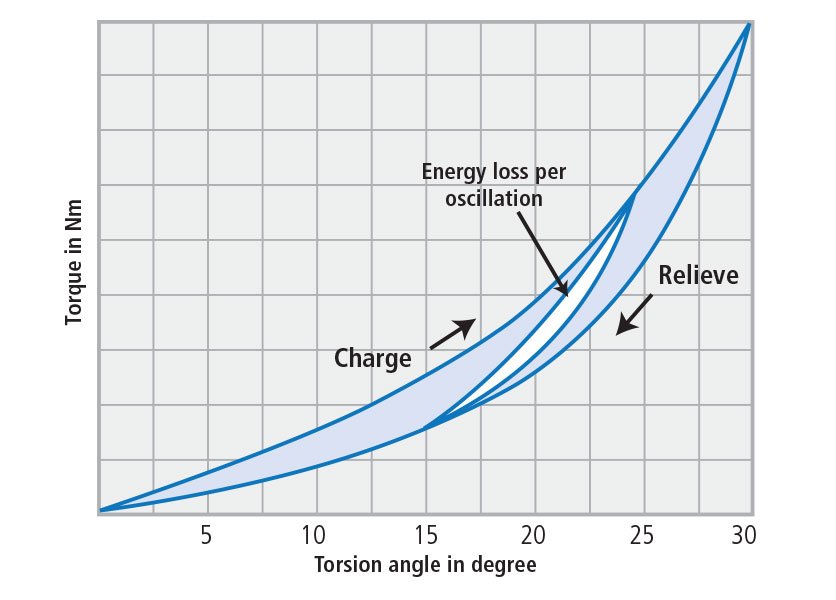

The energy dampening that takes place with the RunRight unit is the resulting energy loss that occurs in the rubber inserts during the pivoting action of the spring device. When the unit is pivoted, part of the created energy generates heat or frictional work. The area between the load and relieve headline indicates the resulting energy loss of the unit. 15% to 20% on average of energy loss occurs when the unit is actuated from the “0” zero position up to 30˚. However, with pre-tensioned units, the actuated working angle is reduced to a few degrees, resulting in a reduced energy loss, see “Energy loss per oscillation” on graph.

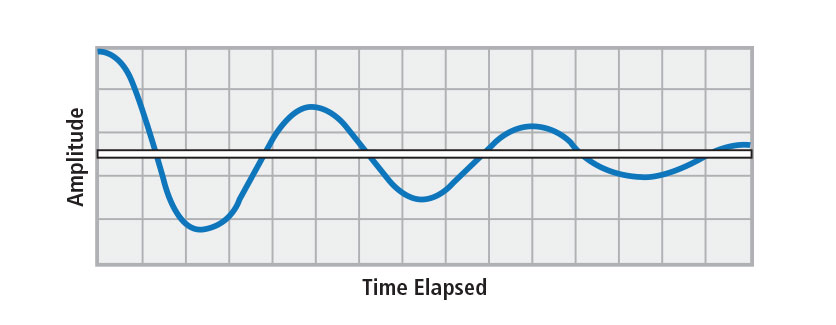

Vigorous unit oscillations fade quickly following each post-pulse oscillation due to the occurring high energy loss. This is an important attribute when using the RunRight unit for screen mountings. The effects of power loss on the screen during normal operation is negligible; however, during the shutdown phase, an important amplitude exaggeration occurs which is close to the resonance frequency of the RunRight unit. Thus the RunRight unit absorbs and dampens the exaggerations, resulting in high energy loss within a few post-pulse oscillations.

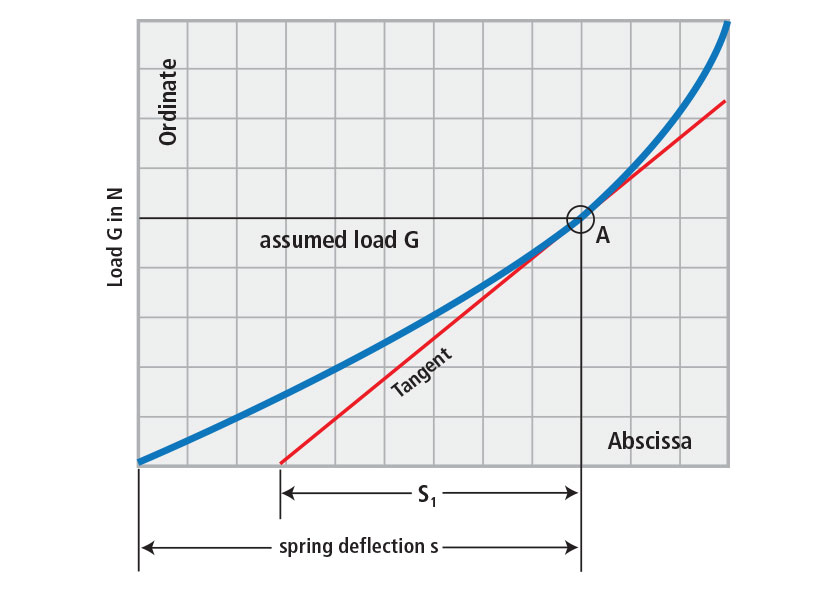

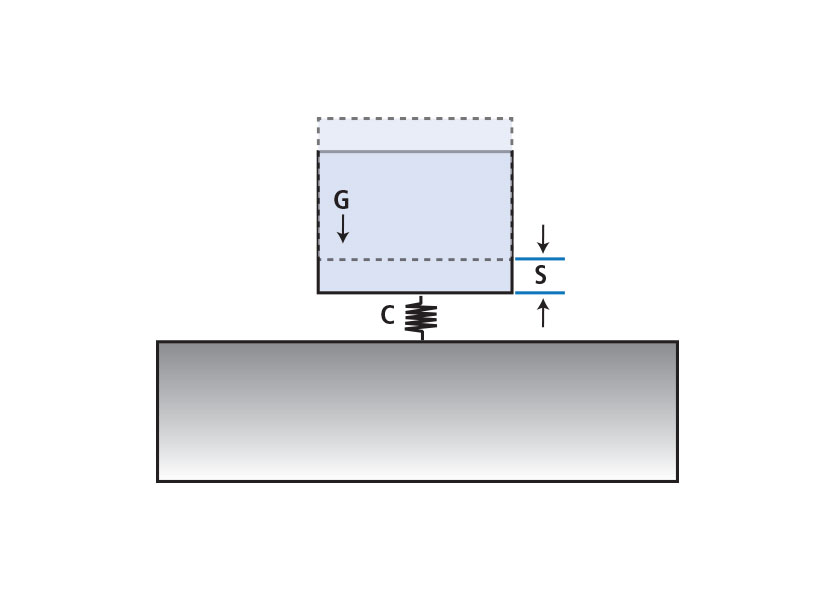

The calculation of the natural frequency of a RunRight™ suspension unit has to be solved by drawing the tangent line at the loading point “A” of the parabolic arc of the load deflection curve. The distance on the axis of the abscissa, i.e. resulting “S”, designates the arithmetical spring deflection in mm which is required for the determination of the natural frequency.

(Natural frequency calculation is shown on page 5 of the RunRight catalog.)

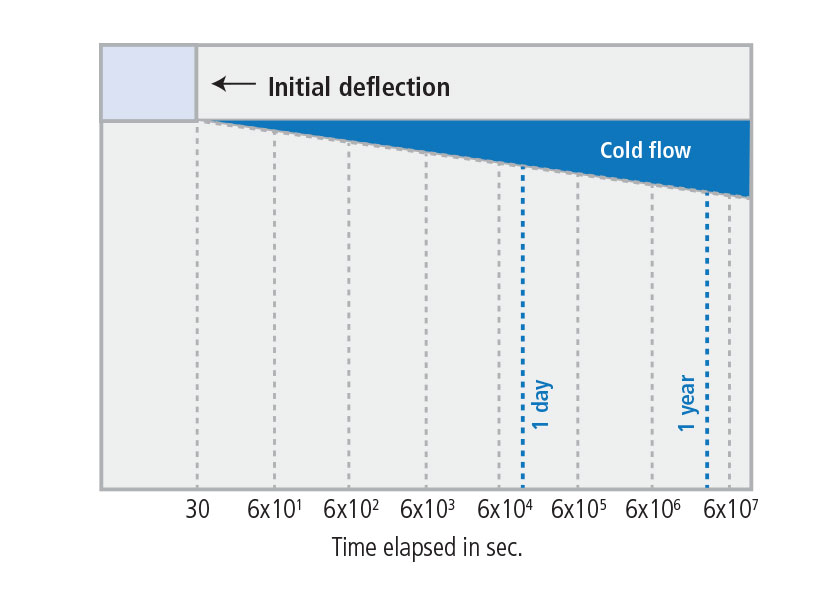

When a load is continually applied to an elastic material, such as the Tensys units, deformation or cold flow occurs. Cold flow appears during a linear logarithmic sequence. The corresponding chart shows that more than 50% of this deformation occurs after only one day of installation. Depending on the environmental temperatures and applied frequencies, after approximately one year of installation near total deformation of the units has occurred. Given the settling factor of a RunRight rubber suspension unit, the inner square will not totally move back to the neutral position of the element. With applications where there are several units in a series or parallel configuration (i.e. the RSC screen mountings) there is approximately +10% of effective cold flow of the nominal deflection curve. This effect must be taken into consideration when using RunRight units on screen mounting or axle bearings designs.

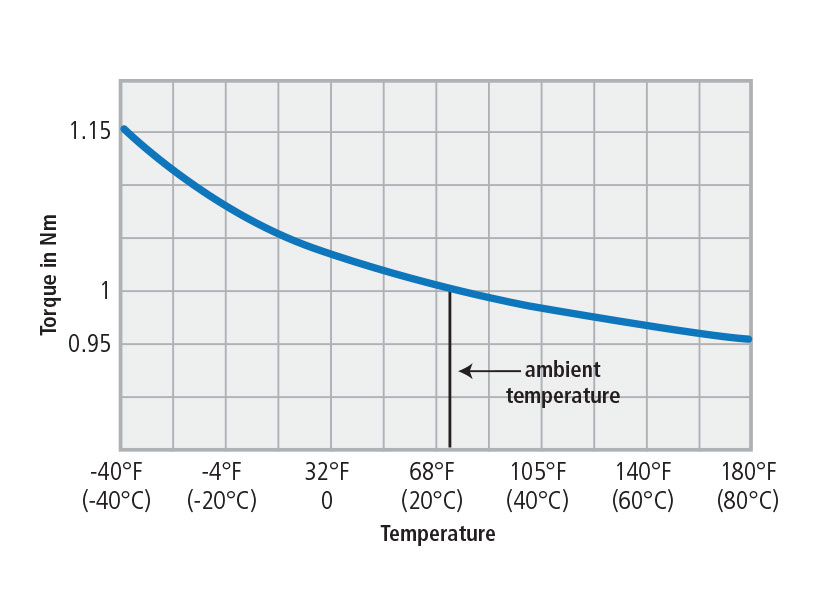

RunRight rubber suspension units manufactured with the Tensys™ 10 elastic inserts are designed to be used between the temperatures of -40˚ to 180˚F (-40˚ to 80˚C). When temperatures rise the mechanical stiffness of the rubber inserts and the resulting element torque will decrease within acceptable tolerances to approximately -5% at 180°F (80˚C). At temperatures below freezing the torsional element stiffness will increase to a maximum of +15% at -40˚F (-40°C). Also, the hysteresis of the RunRight rubber suspension units will increase at lower temperatures and then decrease with rising temperatures. The internal molecular friction caused by the torque applied to the element will warm the rubber inserts in a continuous manner. Therefore, the effective element temperature can vary in relation to the temperature of the environment.

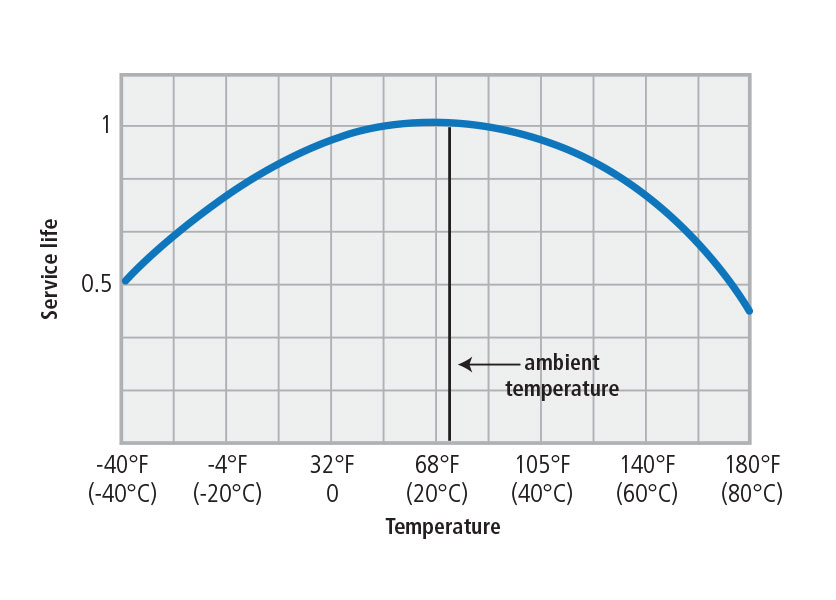

When the rubber suspension units are operating within the specified frequencies, oscillation angles, and recommended surrounding conditions, the unit’s performance and function will be expected to perform for many years. Extremely low or high permanent temperatures will significantly shorten the life expectancy of the rubber suspension units. The Service Life Curve Chart shown to the right shows the life reduction at extreme high and low temperatures using a service life of 1 at the room temperature of 72°F (22˚C).

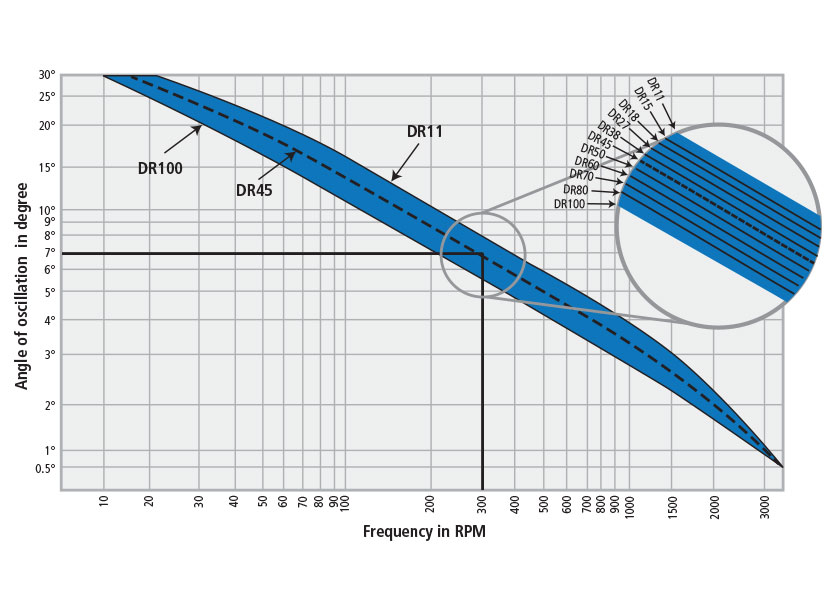

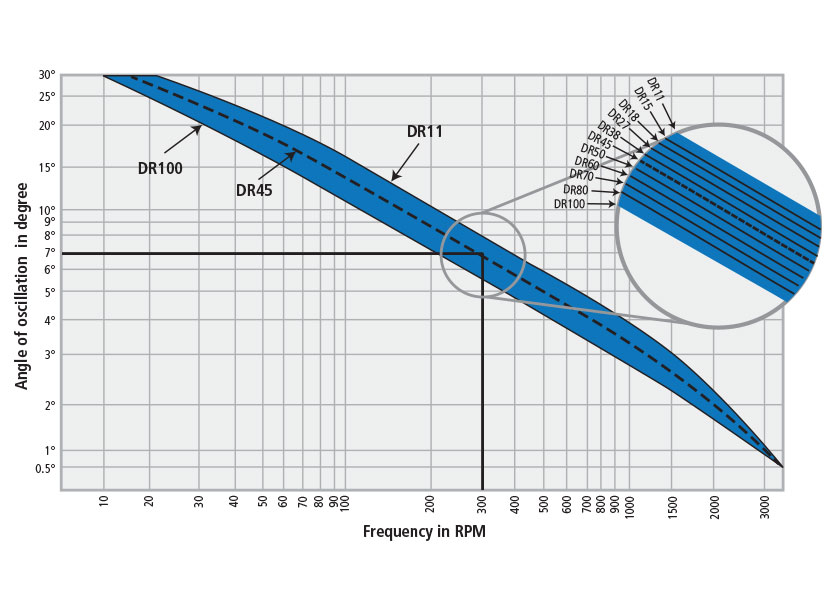

Selection chart below is used for the determination of the maximum allowable frequencies dependent on the rubber suspension unit size (RSS 11, 15, 18, etc.) and the oscillation angle. The higher the frequency, the lower the oscillation angle and the lower the frequency, the higher the oscillation angle as shown in the Allowable Element Frequencies below.

Example: A rubber suspension unit RSS 45 can be rotated from the neutral position of 0˚ to an oscillation angle of +/-7˚ with a maximum frequency of 300 RPM. Contact Lovejoy for applications of “pre-tensioned” elements working, i.e. under 15˚ of pre-tension and describing oscillation angles of +/-5˚ at 300 RPM.

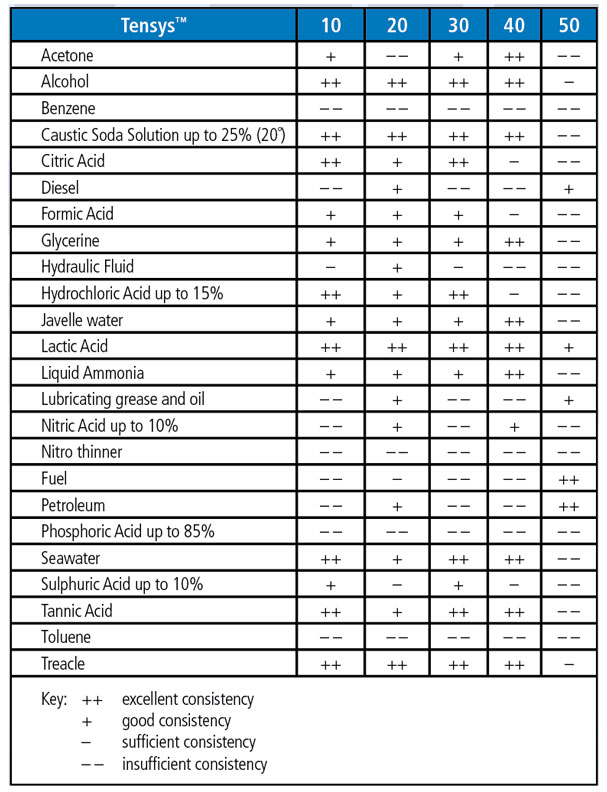

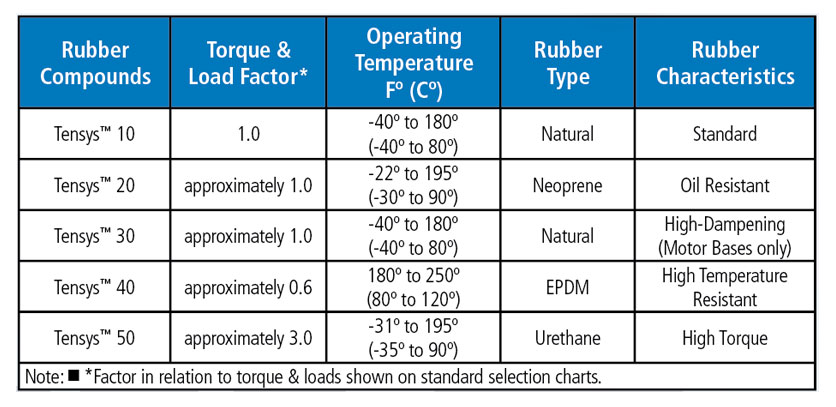

The majority of RunRight™ rubber suspension units are manufactured with Tensys™ 10 natural rubber inserts. The high content of natural rubber in the Tensys 10 offers shape retention, a limited amount of deformation, high mechanical load capabilities and limited hardening of the inserts. Applications requiring high oil resistance, high heat resistance or higher torque capability requires a different elastomeric insert as shown in the chart below.

Standard RunRight rubber suspension units are manufactured with Tensys 10 elastic inserts. The quality of this rubber is due to the high content of natural rubber. This rubber offers a high chemical resistance to many solutions. There are some applications that would require synthetic elastomeric inserts. In these applications Tensys 20 or 40 would be required. When using the synthetic units, the characteristics of the inserts differ slightly, see Rubber Characteristics above for more information. The Chemical Resistance table below is a guideline for chemical compatibility. Please contact Lovejoy for specific applications regarding environmental conditions and the concentration of specific liquids or particulates that would come into contact with the rubber suspension units.