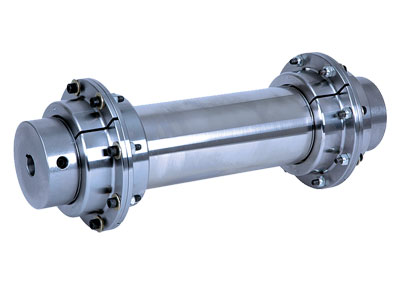

QUICK FLEX Double-Ended Spacer Couplings

- Solid and split covers are designed to accommodate higher speeds and increased torque.

- Inherently balanced from precision machining for high-speed applications.

- Design dampens torsional vibration and shock to help extend life of the coupling and surrounding components.

Resources

QUICK FLEX Double-Ended Spacer Coupling Product Information

Whatever your application demands, you’ll find a wide range of Quick-Flex couplings designed to suit your needs. Choose from multiple insert and cover configurations that withstand some of the most extreme environments.

- Twelve sizes with bores ranging from ranging from 9.4 mm to 285 mm, 0.37 inches to 11.25 inches.

- Designed for continuous torque levels from 0.043 kNm to 188.8 kNm, 377 in-lbs to 1,670,826 in-lbs.

- Designed for peak torque levels from 0.085 kNm to 377.5 kNm, 754 in-lbs to 3,341,562 in-lbs.

- Couplings accept shaft misalignment, up to 2 degrees.

- Split cover options help resist axial separating force under high torque.

- Standard and double-ended spacer couplings available for shaft separations of 25.4 mm to 3,048 mm, 1 inch to 120 inches, for increased application acceptance.

- Four bore options available to meet customers’ needs:

1) Bored, keyed and set screws style – clearance and interference fit;

2) Bushing style; 3) Splined style; and 4) Mill motor style. - Four insert choices for varying torque needs and temperature ranges up to 177° C (350° F).